Dans des secteurs comme la construction, la couverture, le CVC, l’automobile, le maritime et les énergies renouvelables, une étanchéité fiable est essentielle pour garantir la longévité et les performances des structures et des équipements.

Les rubans adhésifs butyle offrent une solution d'étanchéité performante, alliant une forte adhérence à une excellente résistance à l’humidité, aux produits chimiques et aux températures extrêmes.

Dans cet article, nous abordons les cinq principaux avantages of using butyl tape — and explain how tailored converting can maximize efficiency for specific applications.

1. Butyl tape for exceptional waterproofing and airtight sealing

Butyl tapes are highly effective at creating airtight and watertight seals. Thanks to the butyl rubber base, they can maintain a secure bond even when exposed to water, vapor, and high humidity.

Applications:

Scellement roofing membranes and flashing details.

Waterproofing joints in prefabricated concrete structures.

Preventing air and moisture leakage in HVAC ducts.

2. High adhesion to a variety of substrates with butyl tape

Butyl tapes adhere strongly to a wide range of surfaces, including:

Metals (aluminium, steel)

Plastics

Glass

Wood

Concrete

They perform well even on rough, unevenou porous surfaces without the need for primers in most cases.

Applications:

Collage window and door frames in construction projects.

Sealing overlaps on metal roofing sheets.

Montage solar panels on different substrates.

3. Butyl tape for long-term durability and flexibility

Unlike many other sealants, butyl remains flexible over time without hardening or cracking.

It absorbs movement from expansion, contraction, and vibration, ensuring the seal remains intact even under mechanical stress.

Applications:

Expansion joints in facades et cladding systems.

Sealing cable penetrations in data centers et energy storage units.

Flexible sealing in marine vessels subject to constant vibration.

4. An excellent resistance to weathering, UV and chemicals

Top-grade butyl tapes resist:

UV exposure

Oxidation

Chemicals (including mild acids and alkalis)

Temperature fluctuations (cold and heat)

This makes them ideal for outdoor and industrial applications where environmental conditions can be harsh.

Applications:

Weatherproofing roof structures et ventilation outlets.

Sealing joints in greenhouse constructions.

Protecting cable junctions in offshore wind farms.

5. Butyl with for easy and clean application

Butyl tapes are easy to handle and apply:

No curing or drying time is required.

They can be repositioned during application without losing adhesion.

They leave no mess compared to liquid sealants.

This translates into faster and cleaner installations — especially important on large job sites or in production lines.

Applications:

Scellement prefab building modules during assembly.

Fast repairs on metal panels, gutterset roof structures.

Installation of HVAC components without liquid adhesives.

Tailored formats : why is it so important to convert butyl tape

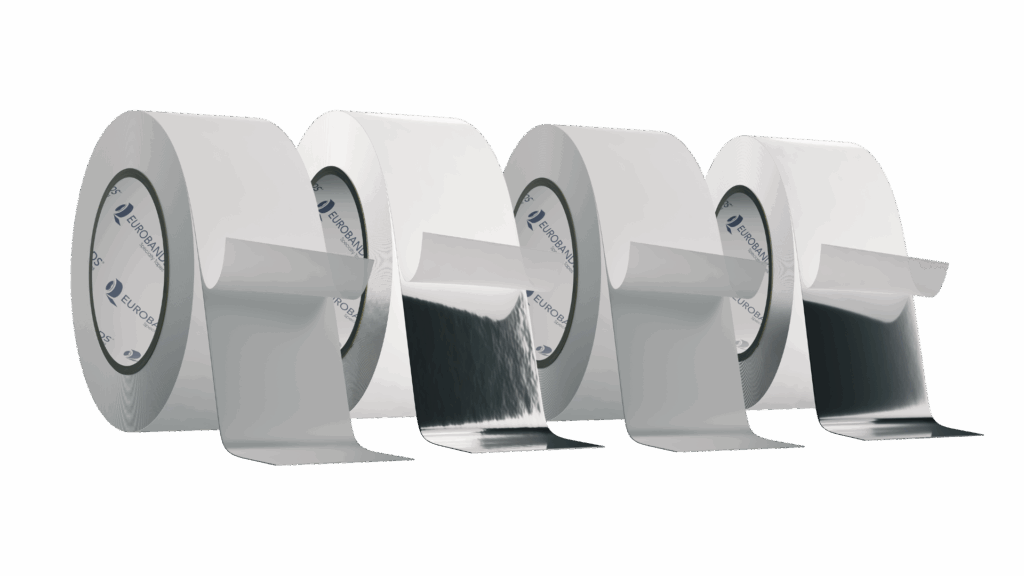

While standard butyl tape rolls suit many tasks, custom formats help optimize installation speed, material use, and system performance.

Nous proposons converting services par exemple :

Custom widths and thicknesses for specific sealing applications.

Die-cut butyl patches for quick, consistent installation.

Pre-cut rolls or strips for modular and prefab construction.

Why customize?

Reduce waste: Pre-sized tapes eliminate unnecessary trimming.

Increase speed: Pre-cut patches or strips speed up repetitive tasks.

Improve seal quality: Consistent shapes and sizes reduce sealing errors.

Industries benefiting from converting:

Construction companies sealing roof and facade panels with custom die-cut butyl seals.

HVAC contractors using narrow strips for fast duct sealing.

Solar and energy sectors installing mounting systems with pre-formed butyl gaskets.

Butyl tapes offer an outstanding combination of waterproofing, adhesion, durability, and ease of use — making them an essential solution for sealing and protecting a wide variety of structures and systems.

By choosing formats convertis, companies can further improve their installation speed, quality, and cost-efficiency.