Why custom adhesive tape matters?

Adhesive tapes are widely used across industries for bonding, sealing, insulating, and protecting materials. However, standard rolls of tape may not always be the most efficient or practical solution for every application.

Customizing adhesive tapes allows manufacturers to enhance productivity, reduce waste, and improve product performance by tailoring tapes to specific shapes, sizes, and functionalities.

From precise die-cut components to specialized multi-layer laminations, discover how custom adhesive tapes can optimize your manufacturing processes and final product performance

How customizing adhesive tape enhances manufacturing efficiency

Optimized product design & application flexibility

Custom adhesive solutions provide greater design freedom, allowing manufacturers to:

- Create complex shapes and structures that fit seamlessly into products

- Design easy-to-handle components for faster application

- Integrate multi-layer materials for enhanced functionality

- Develop non-standard roll widths and lengths to meet exact requirements

By tailoring adhesives to fit your application, you reduce material waste and improve assembly precision.

Faster, cost-effective prototyping

Prototyping is a crucial step in product development, and custom adhesive tapes accelerate the process by providing:

- Rapid sample production to test designs before full-scale manufacturing

- Consistent material performance across prototypes and final products

- Flexibility to experiment with different shapes, adhesives, and backing materials

With custom die-cut adhesive components, manufacturers speed up development cycles while ensuring optimal material efficiency.

Key benefits of customizing your adhesive tape

Improved quality & consistency

Customized adhesive components ensure reliable performance and uniformity, reducing the risk of defects or variability in production. Benefits include:

- Precision cutting & die-cutting for exact component sizing

- Consistent bond strength across all parts

- Minimized product defects, ensuring higher quality control

By eliminating inconsistencies, manufacturers benefit from fewer rejects, less waste, and improved product durability.

Reduced waste & cost savings

Custom-cut tapes help minimize material waste by using only what’s needed, leading to:

- Lower material costs through efficient use of adhesive substrates

- Less scrap and excess material, reducing environmental impact

- Optimized yield per roll, maximizing material efficiency

By improving material utilization, companies lower production costs while maintaining high-quality standards.

Faster assembly & increased production efficiency

Custom adhesive tapes make assembly processes faster and more efficient, thanks to:

- Pre-cut components that eliminate manual trimming and adjustments

- Die-cut alignment features (e.g., location holes) for precise positioning

- Liner designs that allow for easy peeling & application

- Immediate bonding, reducing downtime compared to liquid adhesives

By simplifying tape application, manufacturers can speed up assembly lines and improve production output.

How custom adhesive tape is manufactured

To achieve these benefits, we offer specialized customization processes, including:

🛠 Expert material consultation – Choosing the right adhesive for your application

✂ Precision die-cutting – Creating exact shapes and sizes for seamless integration

📏 Multi-layer lamination – Combining materials for enhanced functionality

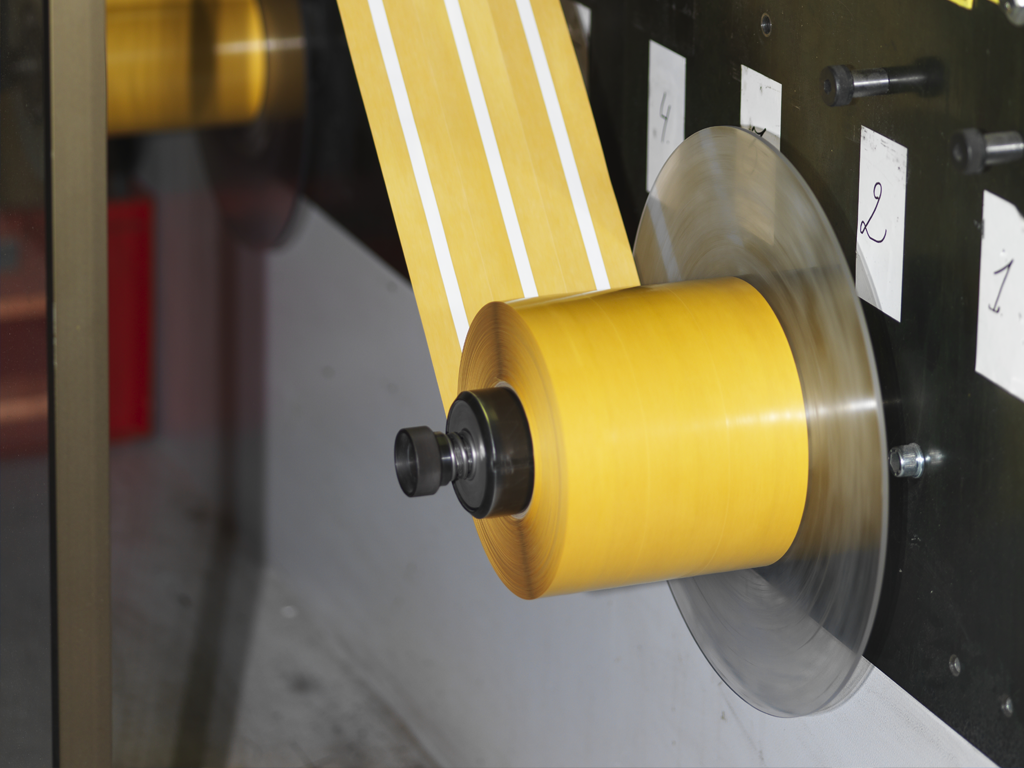

📌 Custom roll slitting – Producing non-standard widths and lengths

⚙ Automated component assembly – Ensuring consistency and efficiency

Customizing adhesive tape transforms manufacturing efficiency, offering faster application, reduced costs, and improved product quality. Whether you need die-cut shapes, multi-layer materials, or precise roll sizes, tailored adhesive solutions help optimize your production process and final product performance.