Adhesive tape converting

Adhesive tape converting is at the core of Eurobands®’ expertise, allowing us to deliver custom solutions tailored to your precise specifications. With advanced equipment and skilled technicians, we offer a range of converting options, including rolls, sheets, die-cuts, and unique dimensions. Our converting services enhance the functionality and ease of use of adhesive tapes across various applications, ensuring that each product is optimized for performance.

SLITTING

Materials (films or adhesive tapes & foams) are stocked in jumbo rolls, which Eurobands® teams cut to size. In this way, and depending on requirements, several types of presentation are possible.

All aspects of the roll cutting process are taken into account, in order to save time on the customer’s production line. Each product is delivered in a finished state, with the ideal dimensions for the customer.

ROTARY DIE CUTTING

Whatever your needs, Eurobands® has the solution for custom cutting through expert adhesive tape converting.

Our teams are committed to delivering transformed or cut materials in the most perfect form, ready for direct use on customers’ production lines to enhance productivity

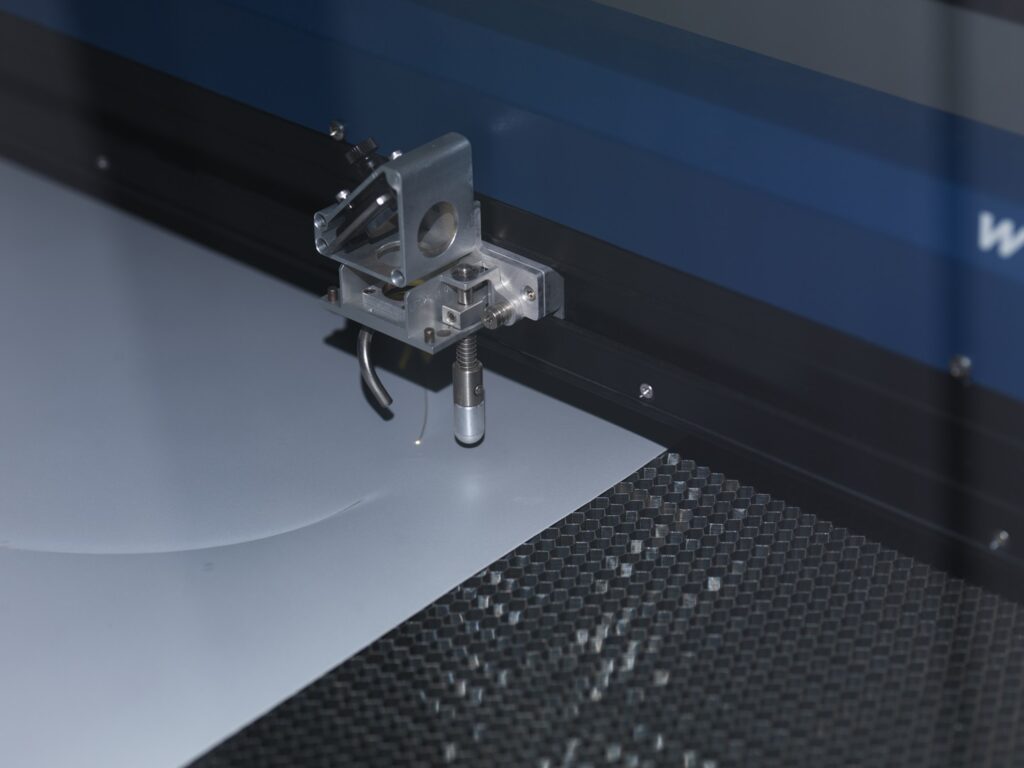

LASER CUTTING

One of the types of cuts suited to adhesive tape converting with laser cutting is kiss cutting, where the top layer is cut without cutting through the underlying layer.

The advantage of laser cutting is that the cutting head does not touch the surface, preventing distortion or sticking. This makes laser cutting ideal for complex cuts, especially when the product’s composition or thickness adds complexity.

Eurobands® machines can also cut through adhesive-coated backings without affecting the release liner.

Other benefits:

- No blades to clean

- Perfectly cut shapes for all types of materials

- Maximum repeatability

- Clean-cut edges

SHEETING

Eurobands® uses various processes to cut all soft and flexible products into specific formats such as A4, A3 or any other size.