Adhesive tape products

Explore our adhesive tape products collection for premium adhesive solutions. With a wide range of single-sided adhesive tapes, double-sided adhesive tapes, and transfer tapes, our selection is tailored to meet your specific needs. Engineered for superior performance and durability, our products ensure reliable adhesion across various industries and applications. Thus, find the perfect adhesive tape for your projects and experience unmatched quality and versatility.

How to choose your adhesive tape products ?

ENVIRONMENT

The environment in

which your product will

be used, depending

on the end use

MATERIALS

MECHANICAL STRESS

PROCESS

Depending on the volumes involved, we will have to adapt our adhesive solutions to production cycles

ADHESIVE TAPE PRODUCTS TECHNICAL SPECIFICATIONS

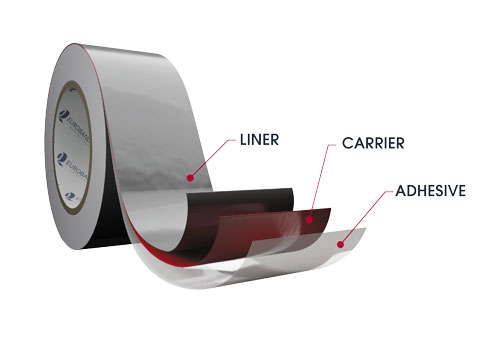

THE CARRIER

The carrier is a flexible material that can be of different composition: paper, films (polypropylene, polyethylene, polyimide (Kapton), polyester, PTFE, PVC, metal (aluminum, copper, lead), rubber, foam, glass cloth…

Each support has its own technical characteristics allowing it to answer specific industrial challenges.

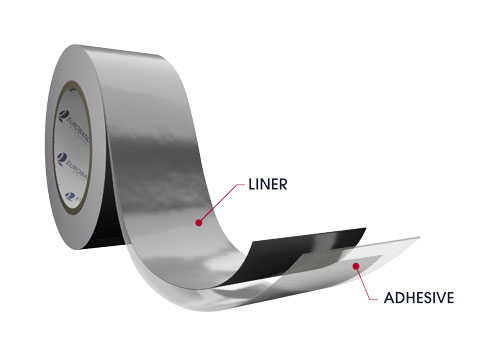

THE LINER

A material that is anti-adhesive and covers the adhesive. The liner prevents the adhesive from sticking to itself. The liner is used as a protection aid during handling/processing and storage. Commonly used liners are:

- Paper liners (e.g. Glassine paper, PE-coated paper, Clay-coated paper)

- Film liners (e.g. PP, PET, PE) Usually, silicone is used as a release system to avoid adhesion between liner material and adhesive.

THE ADHESIVE MASS

Three main families of adhesive mass are distinguished:

- Rubber adhesive mass: its versatility and low cost are its greatest advantages. It has high tack and initial adhesion but limited resistance to high and low temperatures, chemical attack and plasticizers. Indeed, these characteristics make it a good choice for interior applications.

- Acrylic adhesive mass: despite an average initial adhesion, its final adhesion is high, which means that it increases progressively over time. It has good mechanical resistance to aging, UV, cold, humidity, solvents and plasticizers, which makes it a perfect choice for permanent outdoor applications. One of its characteristics is that it is transparent, making it the ideal adhesive for bonding transparent materials.

- Silicone adhesive mass: despite low initial adhesion and poor resistance to hydrocarbons and plasticizers, silicone adhesives have excellent adhesion to silicone materials, excellent resistance to extreme temperatures.

SINGLE SIDED ADHESIVE TAPES & FOAMS

Single-sided adhesive tapes consist of a backing coated on one side with an adhesive. The backing is thin and flexible and may be made from various materials. In addition, this backing is coated with an adhesive selected from one of the three main families: rubber, acrylic or silicone.

DOUBLE SIDED ADHESIVE TAPES & FOAMS

Consist of a substrate or backing coated on both sides with an adhesive. The substrate is coated with an adhesive chosen from one of the three main families: acrylic, silicone or rubber. Moreoever, a release liner applied to one side of the double-sided adhesive tape stops the tape sticking to itself when the tape is wound onto a roll.

TRANSFER TAPES

Acrylic adhesive transfer tapes comprise an adhesive film and a release liner made of kraft paper, polyester or polypropylene. The adhesive film consists exclusively of a “firm” or “soft” acrylic adhesive. Because they are so thin, these doublesided transparent adhesive tapes offer better conformability, moulding more closely to the contact surface of the materials to be assembled.