In construction and industry, ensuring reliable waterproofing is a constant challenge. Waterproof sealing tape provides a durable and efficient solution that prevents water, moisture, and air infiltration. This article explores its applications, benefits, and best practices, while highlighting how converting can adapt solutions to your specific needs.

What is a waterproof sealing tape?

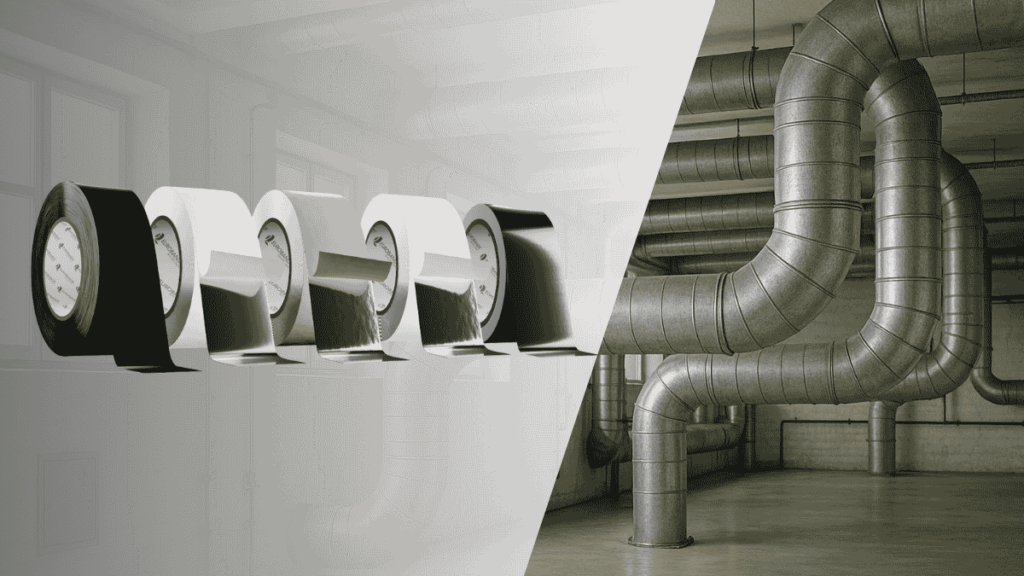

It is an adhesive product range designed to guarantee watertight and airtight joints. It is available in different types depending on the intended use:

Permanent waterproofing tape – for long-term applications in roofing or façades.

Building sealing tape – dedicated to windows, doors, and construction joints.

Moisture barrier tape – preventing condensation in insulation and HVAC systems.

General sealing tape – a versatile option for industrial maintenance and quick fixes.

These tapes are made from materials such as butyl, aluminium, polyethylene (PE), or foam, which makes them suitable for demanding environments like HVAC, construction, appliances, and even marine applications.

Applications of waterproof sealing tape

Building and construction

Roofs and façades: sealing structural joints against rain and wind.

Windows and doors: improving thermal and acoustic insulation.

Insulation systems: joining panels with moisture barrier tape for better efficiency.

HVAC and Industrial systems

Ventilation ducts: sealing with HVAC insulation tape to reduce air loss.

Refrigeration equipment: applying permanent waterproofing tape for reliable sealing.

Condensation protection: barrier tapes preventing leaks and moisture infiltration.

Appliances and maintenance

Quick repairs: sealing porous or cracked surfaces.

Household appliances: protecting components from internal humidity.

Marine industry: waterproofing exposed joints in saltwater conditions.

Key benefits of waterproof sealing tape

Strong waterproofing – effective barrier against water and humidity.

Veelzijdigheid – adhesion on concrete, glass, metal, plastics, and porous surfaces.

Duurzaamheid – resistant to temperature changes, UV exposure, and outdoor stress.

Gebruiksgemak – faster than liquid sealants or welding, with no curing time.

Custom converting options – rolls, die-cuts, and laminates adapted to projects.

Best practices and converting opportunities

Prepare the surface – clean, dry, and dust-free for maximum adhesion.

Select the right tape – e.g., permanent for roofing, barrier tapes for ducts.

Avoid overstretching – ensures consistent sealing performance.

Check compatibility – aluminium, butyl, foam, and PE tapes adapt differently.

Test performance – validate resistance before large-scale use.

Custom converting opportunities

With our adhesive tape converting expertiseWij bieden tailored solutions for every industry:

- Smalle rollen – easy handling for HVAC duct sealing.

- Gestanste patches – convenient for roofing and façade repairs.

- Extra-wide formats – perfect for insulation panel joining.

- Laminated products – aluminium + PE film for enhanced waterproofing performance.

Waterproof sealing tape is a high-performance solution for construction, HVAC, industrial maintenance, and appliances. Its strength, versatility, and custom converting options make it an essential tool for long-lasting waterproofing.

FAQ - Waarom ons tape?

It seals joints and surfaces against water and moisture in construction, HVAC, appliances, and marine environments.

Yes. Permanent waterproofing tapes and aluminium-based solutions are designed to resist UV rays, rain, and temperature fluctuations.

Durability varies by type: permanent solutions last several years, while moisture barrier tapes are suitable for medium-term HVAC applications.

It is faster and easier to apply, with immediate results and no drying time. Sealants may still be useful for irregular or highly flexible joints.