In sectors like HVAC, construction, appliances, automotive, and industrial manufacturing, thermal insulation en moisture protection are critical to maintaining performance, safety, and efficiency.

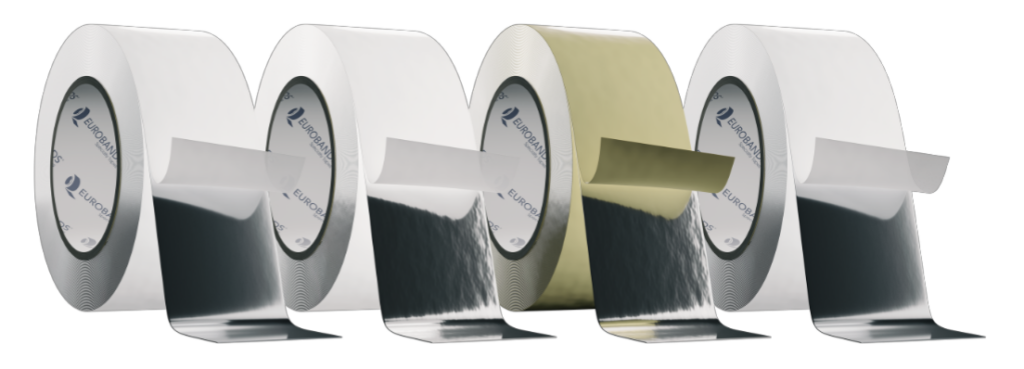

Aluminium tape offer a versatile and highly effective solution for sealing, protecting, and insulating systems against heat, humidity, and aging.

In this article, we explore the vijf belangrijkste voordelen of using aluminium tape — and why professional users increasingly rely on converted, custom formats to optimize their operations.

1. The outstanding heat resistance of aluminium tape

Aluminium tapes are specifically engineered to withstand a wide range of temperatures, from sub-zero conditions up to 150°C or more, depending on the product specification.

They maintain their adhesive strength and sealing properties even when exposed to intense heat.

Applications:

Sealing insulation panels around HVAC ductwork.

Wrapping heating pipes in industrial plants to improve energy efficiency.

Thermal shielding of sensitive components in automotive assemblies.

2. Aluminium tape as an excellent moisture and vapor barrier

Aluminium foil backing creates an effective barrier against moisture, vapor, and certain chemicals. This is crucial in preventing corrosion, condensation, and material degradation over time.

Applications:

Sealing joints in refrigeration systems en cold rooms.

Protecting insulation on rooftops en external walls against rain and humidity.

Moisture sealing around underground piping.

3. A superior durability and logevity

Thanks to its metallic structure, aluminium tape resists:

Tearing and punctures

Aging and drying

UV radiation and chemical attacks

These properties ensure a long service life with minimal maintenance, even under demanding conditions.

Applications:

Protecting solar panel installations from long-term environmental exposure.

Reinforcing thermal insulation on marine vessels.

Weatherproofing outdoor mechanical systems.

4. Aluminium tape for an high conformability for complex surfaces

Modern aluminium tapes are designed for high flexibility, allowing them to adapt to:

Irregular shapes

Sharp edges

Complex contours

This ensures a continuous seal without gaps or lifting, critical for maintaining insulation performance.

Applications:

Sealing around HVAC flanges and fittings.

Insulating irregular pipework in industrial machinery.

Repairing damaged insulation on appliances.

5. The UV, fire and aging resistance of aluminium tape

Premium aluminium tapes are rated for UV resistance and can comply with fire retardant standards (e.g., UL 723).

This is essential for applications where safety, reliability, and regulatory compliance are non-negotiable.

Applications:

External protection of building facades exposed to sunlight.

Fire-resistant sealing in aerospace en public transportation systems.

Insulation finishing in data centers en energy storage facilities.

Tailored formats : why is it so important to convert aluminium tape

While standard aluminium tapes cover many needs, industrial users often benefit from customized formats to improve installation speed, precision, and overall system performance.

Door omzetten aluminium tapes (e.g., op maat snijden, die-cutting, sheeting), we can offer:

Narrow widths for tight or complex sealing areas.

Voorgesneden vormen to speed up insulation and assembly tasks.

Roll lengths adapted to specific production processes (e.g., longer rolls for fewer machine stops).

Why does it matter?

Reduced waste: Tailored sizes fit exactly the application, minimizing scrap.

Faster installation: Pre-cut pieces reduce handling time and improve worker efficiency.

Improved quality: Consistent tape dimensions ensure a more reliable and aesthetic finish.

Industries taking advantage of converting:

HVAC installation companies needing pre-slit aluminium tapes for duct sealing.

Appliance manufacturers using die-cut aluminium patches for thermal shielding.

Automotive suppliers integrating custom tape formats into robotic assembly lines.

De juiste keuze maken aluminium tape is not just about thermal and moisture protection — it’s about ensuring efficiency, duurzaamheiden compliance across a wide range of applications.

With the additional option of custom-converted formats, aluminium tapes can be perfectly adapted to the technical demands of your project.