In industries where speed, precision, and efficiency are critical, adhesive tapes play an essential role. Among the many specialized adhesive solutions available today, fingerlift tapes stand out as one of the most practical innovations. Designed with a liner that extends beyond the adhesive width, fingerlift tapes are engineered to provide faster, easier, and cleaner applications.

What is a Fingerlift Tapes?

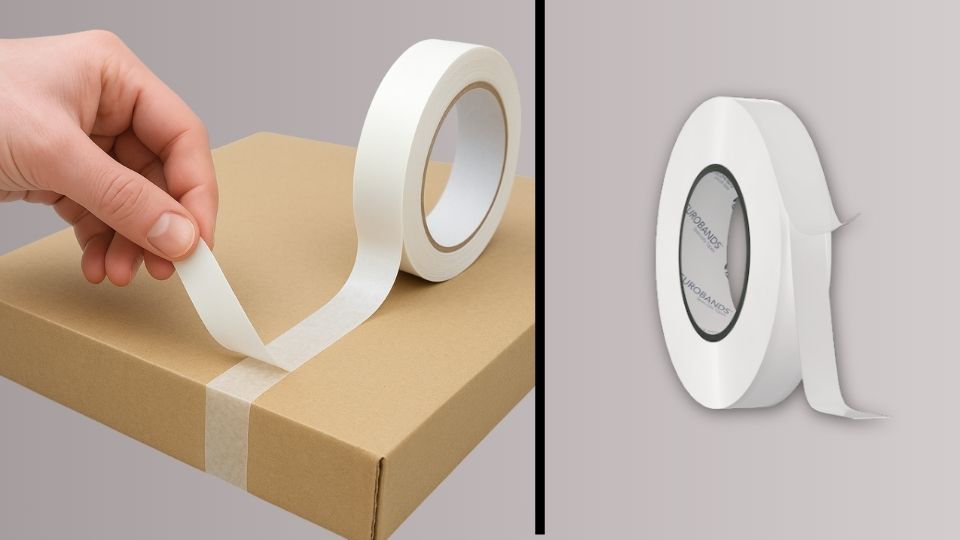

A fingerlift tape is a type of double-sided adhesive tape featuring a release liner that is wider than the adhesive. This design creates a small “fingerlift” area on each side, making it much easier to peel off the liner during application. By eliminating the struggle of separating liner from adhesive, fingerlift tapes speed up workflows and reduce errors.

Key technical characteristics of our fingerlift tapes

Type: Double-sided adhesive tape

Range: Non-woven tissue tapes

Carrier: Tissue paper for flexibility and conformability

Adhesive: Synthetic rubber adhesive offering strong tack and reliability

Liner: White paper liner extending beyond the adhesive width

Thickness: 0.080 mm

Colour: Wit

This combination of features ensures that the tape delivers excellent handling, strong adhesion, and reliable performance in a wide range of applications. Check out our product here.

Why fingerlift tapes are essential

The extended liner design may seem like a small detail, but it has a significant impact on usability and efficiency.

Main advantages include :

- Quick and easy handling – The protruding liner makes peeling fast and effortless.

- Clean application – No adhesive contamination or sticky fingers.

- Consistent results – Reduced risk of misaligned applications.

- Productivity gains – Faster workflows in manual and semi-automated processes.

These qualities make fingerlift tapes indispensable in industries that value speed and accuracy, such as packaging, mailing, print finishing, and display assembly.

Applications of Fingerlift Tapes

Fingerlift tapes are incredibly versatile and can be adapted for a wide range of uses. Below are the main application areas where they provide clear advantages.

Mailing and print finishing

Ideal for direct mail campaigns, envelopes, and brochures.

Fingerlift tapes allow fast, clean, and secure closure without the need for liquid adhesives.

Perfect for print finishing companies that need efficiency during high-volume campaigns.

Point-of-Sale and Displays

Used in retail displays, posters, and promotional stands.

Ensures fast assembly of displays, saving time during installations.

Provides clean adhesion without visible glue marks, maintaining professional aesthetics.

Labels and Packaging

Popular for labels, cartons, and lightweight packaging.

The fingerlift feature accelerates closing and sealing operations.

Replaces liquid adhesives with a neat, mess-free solution.

Industrial Applications

Suitable for light assembly tasks in general manufacturing.

Can be used for temporary or permanent bonding of lightweight components.

Adds efficiency in production environments where precise tape application is required.

Benefits of our fingerlift tapes

Easy handling

The protruding liner eliminates frustration during application. Operators save valuable seconds on every piece, which adds up significantly in large-scale processes.

Strong adhesion

De synthetic rubber adhesive provides a secure bond to a wide range of surfaces, including paper, cardboard, and lightweight plastics.

Clean finish

No excess adhesive or glue residue is left behind. This is especially important in industries where presentation and product quality matter.

Versatility

Fingerlift tapes can be used in diverse sectors, from mailing houses and packaging plants to display manufacturers and industrial converters.

Custom Converting Capabilities

One of the key strengths of our offering lies in our custom converting services. Standard rolls may not always fit the specific requirements of production lines or end applications, which is why we provide tailor-made formats.

Formats available

Rolls – For continuous application in manual or automated processes.

Sheets – Convenient for individual applications.

Die-cut fingerlift formats – Customized shapes and sizes designed to match customer specifications.

Precision converting techniques

Slitting – We produce custom widths and lengths to match production needs.

Roterend stansen – Enables us to create complex shapes with high precision.

Custom fingerlift widths – Adjusted according to handling preferences and application processes.

With these converting capabilities, our clients benefit from adhesive solutions that fit seamlessly into their workflows, eliminating waste and maximizing productivity.

Custom Converting Capabilities

When selecting an adhesive tape supplier, performance and adaptability are crucial. Our fingerlift tapes stand out thanks to:

Product Expertise – A focus on non-woven double-sided tapes designed for efficiency.

Customisation – Converting services tailored to unique production requirements.

Consistency – Reliable adhesive performance that ensures clean, professional results.

Customer Support – Technical assistance to help you select the right format for your application.

By combining high-performance adhesive technology with flexible converting options, we deliver solutions that help businesses work faster, cleaner, and smarter.

Fingerlift tapes represent a simple yet powerful innovation in adhesive technology. By making the liner easier to handle, they save time, improve efficiency, and ensure clean results across a wide variety of applications.

Onze double-sided fingerlift tape, with its non-woven tissue carrier and synthetic rubber adhesive, is engineered to deliver strong adhesion and user-friendly handling. Combined with our custom converting solutions, we provide tailored adhesive formats designed to meet the exact needs of mailing houses, packaging plants, display manufacturers, and general industry.

For businesses looking to improve productivity and application precision, fingerlift tapes are a smart, reliable, and cost-effective choice.

FAQ - Fingerlift tapes

The extended liner makes them significantly easier to handle, improving speed and accuracy in application.

Yes. Our converting capabilities allow us to deliver die-cut formats adapted to unique application requirements.

Absolutely. Rolls can be customized to match automated machinery specifications.

They perform best on paper, cardboard, and lightweight plastics, making them ideal for packaging, print finishing, and displays.