Waarom tape gebruiken als traditionele bevestigingsmethoden zoals schroeven, klinknagels, bouten en vloeibare lijmen al tientallen jaren de industriestandaard zijn voor het verbinden van materialen. Echter, zelfklevende tapes veranderen de moderne productie door een sterk, duurzaam en veelzijdig alternatief.

Van assemblageprocessen stroomlijnen naar de duurzaamheid van producten verbeterenzelfklevende tapes bieden voordelen die mechanische bevestigingsmiddelen kunnen gewoon niet tippen aan. Of je nu werkt in HVACbouw, auto-industrie of elektronicaoverschakelen naar industriële kleefbanden kan leiden tot lichter, sterker en efficiënter productontwerpen.

Ontdek hoe tape is te vergelijken met traditionele bevestigingenzijn belangrijkste voordelenen waar het kan worden toegepast in verschillende industrieën.

Hoe plakband zich verhoudt tot traditionele bevestigingen

Veel fabrikanten vertrouwen nog steeds op mechanische bevestigingen, maar deze methoden gaan vaak gepaard met uitdagingen:

Volumineuze ontwerpen - Schroeven en klinknagels voegen gewicht toe en verstoren gladde oppervlakken.

Materiaal spanning - Boren en bevestigen kan materialen na verloop van tijd verzwakken.

Beperkte flexibiliteit - Traditionele bevestigingen werken mogelijk niet op onregelmatige oppervlakken.

Tijdrovende toepassing - Lassen, schroeven en bouten vereisen extra arbeid en gereedschap.

Het voordeel van tape

✔ Gelijkmatige spanningsverdeling - Voorkomt materiaalmoeheid en barsten.

✔ Lichtgewicht verlijming - Vermindert het productgewicht met behoud van sterkte.

✔ Naadloze esthetiek - Geen zichtbare schroeven of bouten voor een strakke afwerking.

✔ Snelle en eenvoudige toepassing - Boren, lassen of uitharden is niet nodig.

Overschakelen van mechanische bevestigingen op zelfklevende tapes kan productprestaties verbeteren, duurzaamheid verhogen en productie stroomlijnen-En dat alles tegen lagere kosten.

Belangrijkste voordelen van het gebruik van plakband in industriële toepassingen

Ontwerpflexibiliteit en esthetische voordelen

Het gebruik van plakband in uw productontwerp biedt ongeëvenaarde vrijheid en creativiteitwaardoor je:

- Ongelijke materialen verlijmen (bijv. metaal, plastic, glas) zonder compatibiliteitsproblemen.

- Slanke, gladde oppervlakken behouden met een onzichtbare band.

- Gewicht en bulk verminderenwaardoor producten lichter en gemakkelijker te hanteren zijn.

- Boren en lassen overbodig makenDe integriteit van breekbare of warmtegevoelige materialen behouden.

Door integratie van toepassingenkunnen fabrikanten sterkere, meer innovatieve producten te creëren met een moderne esthetiek.

Verbeterde productprestaties en duurzaamheid

Tapes hechten niet alleen materialen - ze verbeteren de algehele productkwaliteit door het volgende te bieden extra bescherming en betrouwbaarheid:

- Bestand tegen schokken en trillingen - Ideaal voor auto's, elektronica en bouwtoepassingen.

- Corrosiebescherming - Geen risico op roest of materiaalvervorming.

- Superieure omgevingsweerstand - Bestand tegen vocht, extreme temperaturen en chemicaliën.

- Afdichtingsmogelijkheden - Voorkomt verontreinigingen, stof en binnendringend waterwaardoor de levensduur van het product wordt verlengd.

Door stress te verdelen gelijkmatig over de gelijmde oppervlakkenkleefbanden materiaalmoeheid verminderen en het risico op storingen te minimaliseren.

Verbeterde productie-efficiëntie en kostenbesparingen

Overschakelen op zelfklevende tapes kan assemblageprocessen stroomlijnenarbeidskosten te verlagen en de productie-efficiëntie te verbeteren. De belangrijkste voordelen zijn:

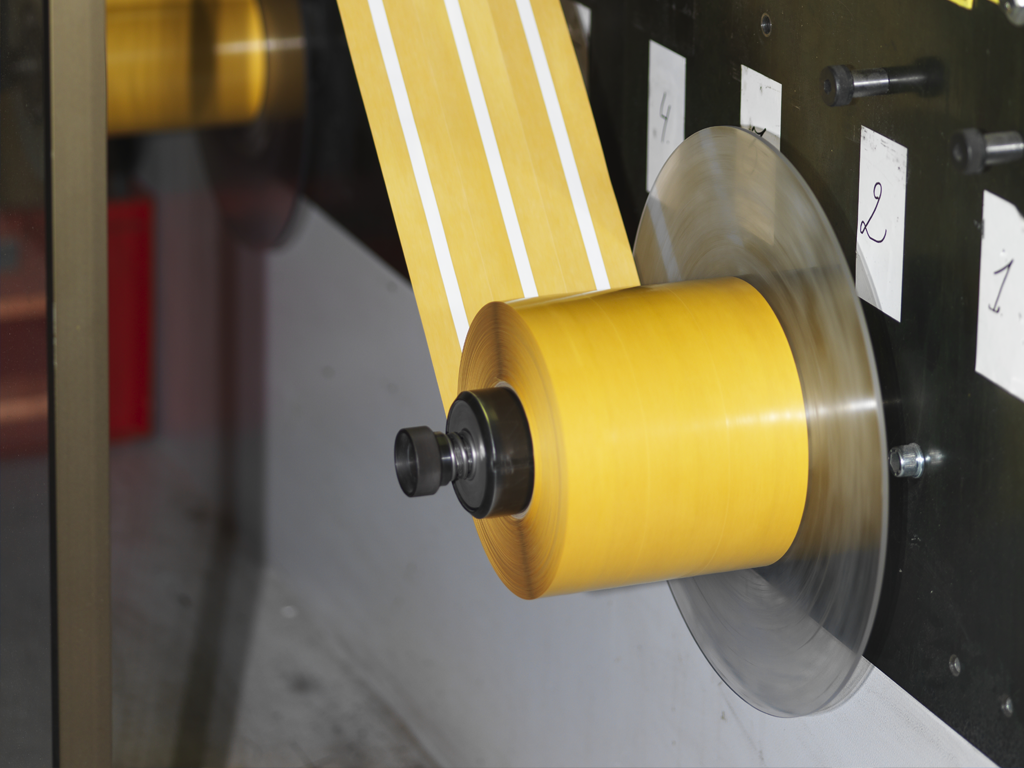

- Snellere toepassing - Gestanste tapes zijn direct aan te brengen, zodat er minder montagetijd nodig is.

- Minder gereedschap nodig - Geen schroeven, bouten, lassen of slijpen nodig.

- Geen uithardings- of droogtijd - In tegenstelling tot vloeibare lijmen bieden tapes onmiddellijke verwerkingskracht.

- Geautomatiseerde applicatiecompatibiliteit - Werkt naadloos in productielijnen met hoge snelheid.

Door elimineren van extra productiestappenkleefbanden kosten te besparen en de efficiëntie van de workflow te verbeteren.

Toepassingen : Waar kun je zelfklevende tapes gebruiken?

Plakband wordt gebruikt in een breed scala aan industrieënbiedt betrouwbare hechting en extra functionaliteit:

HVAC & Isolatie

- Afdichting kanalen en leidingen om luchtlekken te voorkomen

- aanbieden elektrische isolatie in hoogspanningsomgevingen

Auto's & Vervoer

- Verbinding lichte panelen om de brandstofefficiëntie te verbeteren

- Lawaai, trillingen en ruwheid (NVH) verminderen

Elektronica en elektronica

- Isolerend draden en circuits voor veiligheid en duurzaamheid

- Aanbod thermisch beheer voor warmtegevoelige componenten

Bouw & Architectuur

- Montage glas, gevels en bewegwijzering zonder zichtbare bevestigingen

- Afdichten en weerbestendig maken ramen en panelen

Met hun veelzijdige toepassingen en sterke prestatieszelfklevende tapes worden een voorkeurskeuze in alle sectoren.

Industrieën blijven innoveren, zelfklevende tapes vervangen traditionele bevestigingen door het aanbieden van sterkere, lichtere en veelzijdigere hechtoplossingen. Van productontwerp verbeteren naar duurzaamheid en efficiëntie verbeterenbanden kosten verlagen en tegelijkertijd prestaties verhogen-ze maken een essentieel hulpmiddel in de moderne productie.

FAQ - Waarom ons tape?

Plakband biedt verschillende voordelen ten opzichte van traditionele bevestigingen zoals schroeven, klinknagels en vloeibare lijmen:

- Lichtgewicht en ruimtebesparend - Geen omvangrijke bevestigingen, waardoor het product lichter en kleiner wordt.

- Gelijkmatige spanningsverdeling - Voorkomt materiaalmoeheid, scheuren en spanningspunten.

- Snelle en eenvoudige toepassing - Boren, lassen of uitharden is niet nodig.

- Verbeterde esthetiek - Biedt een onzichtbare band voor een gladde, schone afwerking.

- Afdichting en bescherming - Voorkomt dat vocht, stof en verontreinigingen de onderdelen binnendringen.

- Bestand tegen schokken en trillingen - Vermindert lawaai en verhoogt de duurzaamheid van het product.

Deze voordelen maken zelfklevende tapes tot een veelzijdig en efficiënt alternatief voor industriële en productietoepassingen.

Plakbanden worden veel gebruikt in verschillende industrieën voor lijmen, afdichten, beschermen, isoleren en markeren. Enkele veelvoorkomende toepassingen zijn:

- HVAC & Isolatie - Kanalen afdichten en thermische bescherming bieden.

- Auto's & Vervoer - Vermindering van gewicht, verlijming van panelen en trillingsdemping.

- Elektronica en elektronica - Isoleren van circuits en warmtegevoelige componenten.

- Bouw & Architectuur - Montage van glas, bewegwijzering en weerbestendigheid.

- Verpakking en etikettering - Zendingen beveiligen en identificeren.

Of in fabricage, reparatie of assemblagekleefbanden efficiëntie en duurzaamheid verbeteren in vele industrieën.

In het verleden werden kleefbanden voornamelijk gebruikt voor basisafdichting en tijdelijke reparatieszoals:

- Papier & verpakkingstapes - Gebruikt voor het verzegelen van dozen en documenten.

- Afplakband - Oorspronkelijk ontwikkeld voor schilders om strakke lijnen te creëren.

- Elektrische isolatietape - Elektrische aansluitingen beschermen tegen vocht en kortsluiting.

- Medische en chirurgische tapes - Verbanden en medische hulpmiddelen vastzetten.

In de loop der tijd hebben verbeteringen in lijmtechnologie hun toepassingen uitgebreid, waardoor ze essentieel zijn geworden voor industriële verlijming, structurele assemblage en beschermende oplossingen in verschillende sectoren.