Precision die-cut adhesive tapes for high-volume production

Rotary die-cutting is a high-precision converting technique used to shape adhesive tapes into customized forms suited for industrial applications. In Poland, our die-cutting services support sectors such as electrical insulation, appliance manufacturing, and electronics, where precise and efficient tape components are required for optimal performance.

By leveraging advanced rotary die-cutting technology, we provide pre-cut adhesive solutions that streamline assembly, improve efficiency, and minimize waste in high-volume production environments.

Understanding Rotary Die-Cutting for Adhesive Tapes

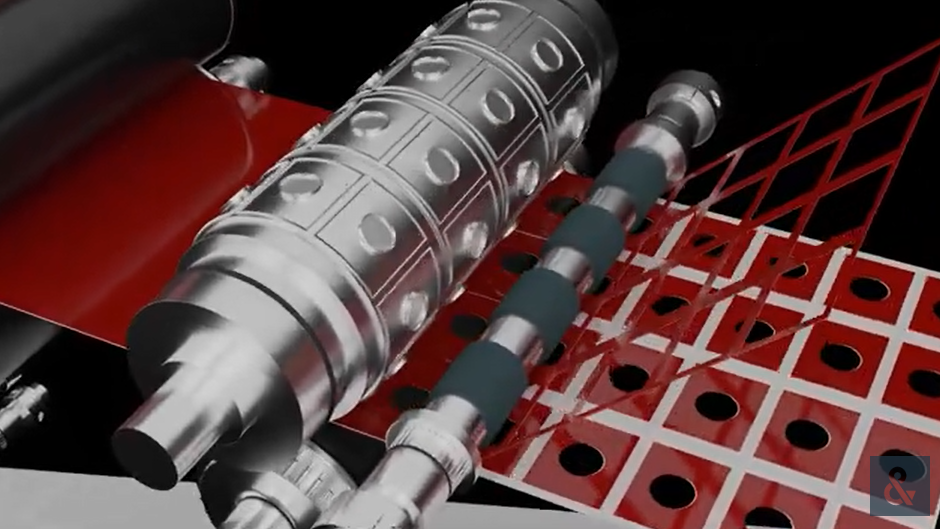

Rotary die-cutting is a continuous, high-speed process that shapes adhesive materials into custom designs. Using a cylindrical die, this method ensures consistent and accurate cuts, making it ideal for high-volume applications.

The process follows these steps:

- The adhesive material is unwound from a roll and fed into the rotary die-cutting machine.

- A precision-engraved die cylinder cuts the material into specific shapes with exact tolerances.

- Excess material, or “matrix waste,” is efficiently removed, leaving only pre-cut adhesive components.

This automated process ensures fast, repeatable, and highly accurate production, making it an essential solution for industries requiring specialized adhesive parts.

Why die-cut adhesive tapes?

Industries benefit from die-cut tapes because they:

- Enhance application efficiency – Eliminates manual cutting, reducing labor time.

- Ensure consistency – Every piece meets strict dimensional accuracy.

- Optimize material usage – Minimizes waste, leading to cost savings.

- Improve performance – Custom-shaped tapes provide better fit and adhesion in complex applications.

Key advantages of rotary die-cutting

Scalable, high-speed production

Rotary die-cutting supports continuous, high-volume processing, making it suitable for large-scale industrial applications.

Exceptional Precision and Repeatability

With computer-controlled cutting systems, our custom die-cut tapes meet tight tolerance requirements, ensuring reliable application in electronics and insulation.

Minimal Waste, Maximum Efficiency

By optimizing material usage, this process reduces production costs while maintaining high output quality.

Compatibility with Various Adhesive Materials

Our die-cutting solutions accommodate a range of specialized adhesives, including:

- Electrical insulation tapes for wiring protection and transformer insulation.

- Thermal conductive tapes for heat management in electronic devices.

- Protective films for surface shielding in home appliances and industrial equipment

Applications of rotary die-cut in Poland

Electrical insulation & cable management

Custom die-cut insulation tapes are essential for power distribution systems, electrical panels, and wiring harnesses. They provide:

- Precise insulation for high-voltage applications.

- EMI/RFI shielding to prevent signal interference.

- Flame-retardant solutions for enhanced electrical safety

Appliance manufacturing & component protection

The home appliance industry relies on custom protective and assembly tapes for damage prevention and seamless production. Typical applications include:

- Protecting stainless steel and glass surfaces from scratches during handling.

- Sealing refrigerator and oven doors with pre-cut foam tapes.

- Adhesive bonding solutions for structural and aesthetic components.

Electronics & consumer devices

Die-cut adhesive tapes support the production of modern electronic devices, ensuring reliability and durability. They are used for:

- Heat dissipation and thermal insulation in circuit boards.

- Protective films for LCD and OLED screens.

- Conductive and insulating layers in battery packs.

Why die-cutting in Poland ensures quality?

Our Poland-based die-cutting facility provides high-quality precision cutting, tailored for industries that require accuracy, efficiency, and scalability. We guarantee:

- Advanced die-cutting technology for clean, burr-free cuts.

- Expertise in handling complex adhesive materials, such as insulation, conductive, and thermal tapes.

- Comprehensive quality control, ensuring each batch meets industry standards.

- Flexible production runs, from custom prototypes to large-scale orders.

By choosing a local converting partner in Poland, businesses benefit from faster delivery times, reduced logistics costs, and enhanced supply chain reliability.

Custom die-cutting in Poland from leading brands

We process and convert high-performance adhesive tapes from leading brands such as Tesa, 3M, and Nitto, offering industry-trusted solutions.

In addition to converting top-tier brands, we also provide our own private-label adhesive tapes, offering cost-effective, application-specific alternatives designed to meet the demands of Polish industries.