Butyl adhesive tapes for sealing and waterproofing

Butyl adhesive tapes are ideal for sealing, moisture protection, and acoustic damping in challenging environments. Known for their flexibility, strong tack, and excellent adhesion to rough or irregular surfaces, they are widely used in construction, HVAC systems, transport, and building envelopes.

As a manufacturer and converter, we supply butyl tapes in custom roll sizes and formats — including laminated structures or die-cut parts, tailored to your process, whether manual or automated.

Our butyl tapes

-

Sealing butyl tape – 08028

Read more -

Butyl / PE tapes – 08030

Read more -

Indoor HVAC insultation tape – 08008

Read more -

Adhesive tape for porous surface – 08035

Read more -

Permanent sealing tape – 08034

Read more -

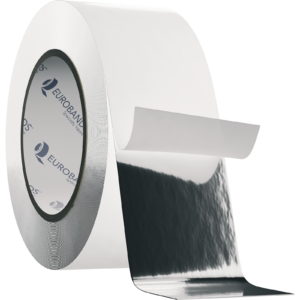

Butyl/Aluminium tapes – 08031

Read more -

Permanent waterproofing tape – 08029

Read more -

Compression joint seal tape – 38042

Read more -

HVAC insulation tape – 38040

Read more -

Butyl tapes – 38042

Read more -

Butyl tapes – 38040

Read more

Have a question ?

Would you like to talk to our experts? Do you have any questions? Would you like a sample?

What is butyl adhesive tape?

Butyl tapes are made from synthetic rubber-based adhesives (butyl rubber) that remain permanently flexible and provide strong adhesion to porous or uneven materials. Unlike acrylic or hotmelt tapes, butyl stays tacky and soft, making it ideal for long-term sealing, even under temperature or pressure changes.

They are often backed with aluminium foil, PE film, or non-woven fabrics, depending on the use. Butyl adhesive tapes are especially suited for joint sealing, roof overlaps, and panel assembly in both interior and exterior environments.

When should you use butyl tape?

Use cases:

Waterproofing and air sealing in roofing, façades, or window systems

Vapor barrier overlaps in insulation projects

Soundproofing joints in automotive and HVAC

Flexible sealing between metal, plastic, wood, or concrete

Anti-vibration and weatherproofing in enclosures and mechanical assemblies

Because butyl tapes adhere even to dusty, rough, or oily surfaces, they’re often preferred when standard pressure-sensitive adhesives fail.

Slitting and converting: solving sealing and installation challenges

Standard butyl rolls often come in generic sizes that don’t match the real-life constraints of your installation or production process. That’s where tape converting comes in — helping you save time, reduce waste, and improve efficiency.

Slitted rolls

We supply butyl tapes in custom roll widths and lengths, perfectly adapted to:

Manual on-site installation

Narrow joints or panel edges

Use with specific dispensers or tools

Reduced material overlap and waste

By adapting the tape format to your exact need, you gain cleaner application, better ergonomics, and time saved on every job.

Converted parts

We also produce die-cut pieces, ready to use directly in your assembly process:

Pre-cut lengths for structural joints

Die-cut patches or strips for façade and roof sealing

Tabbed formats for easier liner removal

Laminated combinations for extra strength or UV resistance

Converting transforms a standard tape into a tailor-made solution — reducing handling time, standardizing application, and improving performance across HVAC, construction, and transport industries.